CONTINUOUS ACTUATORS

Continuous actuators allow a system to position or adjust outputs over a wide

range of values. Even in their simplest form, continuous actuators tend to be mechanically

complex devices. For example, a linear slide system might be composed of a motor with

an electronic controller driving a mechanical slide with a ball screw. The cost for such an

actuators can easily be higher than for the control system itself. These actuators also

require sophisticated control techniques that will be discussed in later chapters. In general,

when there is a choice, it is better to use discrete actuators to reduce costs and complexity.

ELECTRIC MOTORS

An electric motor is composed of a rotating center, called the rotor, and a stationary

outside, called the stator. These motors use the attraction and repulsion of magnetic

fields to induce forces, and hence motion. Typical electric motors use at least one electromagnetic

coil, and sometimes permanent magnets to set up opposing fields. When an voltage

is applied to these coils the result is a torque and rotation of an output shaft. There are

a variety of motor configuration the yields motors suitable for different applications. Most

notably, as the voltages supplied to the motors will vary the speeds and torques that they

will provide.

A control system is required when a motor is used for an application that requires

continuous position or velocity. In any controlled

system a command generator is required to specify a desired position. The controller

will compare the feedback from the encoder to the desired position or velocity to

determine the system error. The controller with then generate an output, based on the system

error. The output is then passed through a power amplifier, which in turn drives the

motor. The encoder is connected directly to the motor shaft to provide feedback of position.

DC BRUSHED MOTORS

In a DC motor there is normally a set of coils on the rotor that turn inside a stator

populated with permanent magnets. The magnetics provide a permanent magnetic field for the rotor to push against. When current is run through the wire loop it creates a magnetic field.

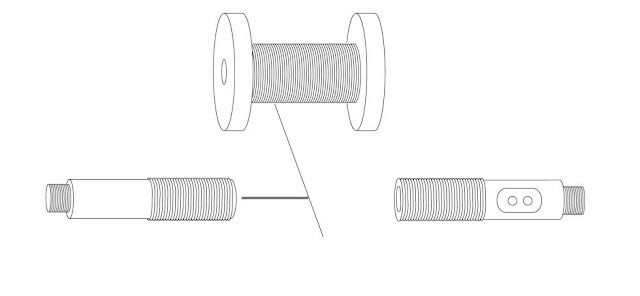

The power is delivered to the rotor using a commutator and brushes. In the figure the power is supplied to the rotor through graphite brushes rubbing

against the commutator. The commutator is split so that every half revolution the

polarity of the voltage on the rotor, and the induced magnetic field reverses to push against

the permanent magnets.

The direction of rotation will be determined by the polarity of the applied voltage,

and the speed is proportional to the voltage. A feedback controller is used with these

motors to provide motor positioning and velocity control.

These motors are losing popularity to brushless motors. The brushes are subject to

wear, which increases maintenance costs. In addition, the use of brushes increases resistance,

and lowers the motors efficiency.

AC SYNCHRONOUS MOTORS

A synchronous motor has the windings on the stator. The rotor is normally a squirrel

cage design. The squirrel cage is a cast aluminum core that when exposed to a changing

magnetic field will set up an opposing field. When an AC voltage is applied to the

stator coils an AC magnetic field is created, the squirrel cage sets up an opposing magnetic

field and the resulting torque causes the motor to turn.

The motor is called synchronous because the rotor will turn at a frequency close to

that of the applied voltage, but there is always some slip. It is possible to control the speed

of the motor by controlling the frequency of the AC voltage. Synchronous motor drives

control the speed of the motors by synthesizing a variable frequency AC waveform.

These drives should be used for applications that only require a single rotation

direction. The torque speed curve for a typical induction motor is shown in Figure 368.

When the motor is used with a fixed frequency AC source the synchronous speed of the

motor will be the frequency of AC voltage multiplied by the number of poles in the motor.

The motor actually has the maximum torque below the synchronous speed. For example a

motor 2 pole motor might have a synchronous speed of (2*60*60/2) 1800 RPM, but be

rated for 1720 RPM. When a feedback controller is used the issue of slip becomes insignificant.

BRUSHLESS DC MOTORS

Brushless motors use a permanent magnet on the rotor, and user wire windings on

the stator. Therefore there is no need to use brushes and a commutator to switch the polarity of the voltage on the coil. The lack of brushes means that these motors require less

maintenance than the brushed DC motors.

To continuously rotate these motors the current in the outer coils must alternate

continuously. If the power supplied to the coils is an AC sinusoidal waveform, the motor

will behave like an AC motor. The applied voltage can also be trapezoidal, which will give

a similar effect. The changing waveforms are controller using position feedback from the

motor to select switching times. The speed of the motor is proportional to the frequency of

the signaL.

STEPPER MOTORS

Stepper motors are designed for positioning. They move one step at a time with a

typical step size of 1.8 degrees giving 200 steps per revolution. Other motors are designed

for step sizes of 2, 2.5, 5, 15 and 30 degrees.

There are two basic types of stepper motors, unipolar and bipolar, as shown in Figure

370. The unipolar uses center tapped windings and can use a single power supply. The

bipolar motor is simpler but requires a positive and negative supply and more complex

switching circuitry.

to be continued

range of values. Even in their simplest form, continuous actuators tend to be mechanically

complex devices. For example, a linear slide system might be composed of a motor with

an electronic controller driving a mechanical slide with a ball screw. The cost for such an

actuators can easily be higher than for the control system itself. These actuators also

require sophisticated control techniques that will be discussed in later chapters. In general,

when there is a choice, it is better to use discrete actuators to reduce costs and complexity.

ELECTRIC MOTORS

An electric motor is composed of a rotating center, called the rotor, and a stationary

outside, called the stator. These motors use the attraction and repulsion of magnetic

fields to induce forces, and hence motion. Typical electric motors use at least one electromagnetic

coil, and sometimes permanent magnets to set up opposing fields. When an voltage

is applied to these coils the result is a torque and rotation of an output shaft. There are

a variety of motor configuration the yields motors suitable for different applications. Most

notably, as the voltages supplied to the motors will vary the speeds and torques that they

will provide.

A control system is required when a motor is used for an application that requires

continuous position or velocity. In any controlled

system a command generator is required to specify a desired position. The controller

will compare the feedback from the encoder to the desired position or velocity to

determine the system error. The controller with then generate an output, based on the system

error. The output is then passed through a power amplifier, which in turn drives the

motor. The encoder is connected directly to the motor shaft to provide feedback of position.

DC BRUSHED MOTORS

In a DC motor there is normally a set of coils on the rotor that turn inside a stator

populated with permanent magnets. The magnetics provide a permanent magnetic field for the rotor to push against. When current is run through the wire loop it creates a magnetic field.

The power is delivered to the rotor using a commutator and brushes. In the figure the power is supplied to the rotor through graphite brushes rubbing

against the commutator. The commutator is split so that every half revolution the

polarity of the voltage on the rotor, and the induced magnetic field reverses to push against

the permanent magnets.

The direction of rotation will be determined by the polarity of the applied voltage,

and the speed is proportional to the voltage. A feedback controller is used with these

motors to provide motor positioning and velocity control.

These motors are losing popularity to brushless motors. The brushes are subject to

wear, which increases maintenance costs. In addition, the use of brushes increases resistance,

and lowers the motors efficiency.

AC SYNCHRONOUS MOTORS

A synchronous motor has the windings on the stator. The rotor is normally a squirrel

cage design. The squirrel cage is a cast aluminum core that when exposed to a changing

magnetic field will set up an opposing field. When an AC voltage is applied to the

stator coils an AC magnetic field is created, the squirrel cage sets up an opposing magnetic

field and the resulting torque causes the motor to turn.

The motor is called synchronous because the rotor will turn at a frequency close to

that of the applied voltage, but there is always some slip. It is possible to control the speed

of the motor by controlling the frequency of the AC voltage. Synchronous motor drives

control the speed of the motors by synthesizing a variable frequency AC waveform.

These drives should be used for applications that only require a single rotation

direction. The torque speed curve for a typical induction motor is shown in Figure 368.

When the motor is used with a fixed frequency AC source the synchronous speed of the

motor will be the frequency of AC voltage multiplied by the number of poles in the motor.

The motor actually has the maximum torque below the synchronous speed. For example a

motor 2 pole motor might have a synchronous speed of (2*60*60/2) 1800 RPM, but be

rated for 1720 RPM. When a feedback controller is used the issue of slip becomes insignificant.

BRUSHLESS DC MOTORS

Brushless motors use a permanent magnet on the rotor, and user wire windings on

the stator. Therefore there is no need to use brushes and a commutator to switch the polarity of the voltage on the coil. The lack of brushes means that these motors require less

maintenance than the brushed DC motors.

To continuously rotate these motors the current in the outer coils must alternate

continuously. If the power supplied to the coils is an AC sinusoidal waveform, the motor

will behave like an AC motor. The applied voltage can also be trapezoidal, which will give

a similar effect. The changing waveforms are controller using position feedback from the

motor to select switching times. The speed of the motor is proportional to the frequency of

the signaL.

STEPPER MOTORS

Stepper motors are designed for positioning. They move one step at a time with a

typical step size of 1.8 degrees giving 200 steps per revolution. Other motors are designed

for step sizes of 2, 2.5, 5, 15 and 30 degrees.

There are two basic types of stepper motors, unipolar and bipolar, as shown in Figure

370. The unipolar uses center tapped windings and can use a single power supply. The

bipolar motor is simpler but requires a positive and negative supply and more complex

switching circuitry.

to be continued